In the late 15th century, Leonardo da Vinci, the ultimate Renaissance man, sketched a curious design called the “aerial screw.” This spiral-shaped rotor, meant to lift off the ground like a helicopter, was a bold vision of human flight. Fast forward to 2025, and this 500-year-old idea is inspiring engineers to solve real-world problems with drones. From reducing noise pollution to improving energy efficiency, da Vinci’s aerial screw is proving that genius ideas never go out of style.

What Is Leonardo da Vinci’s Aerial Screw?

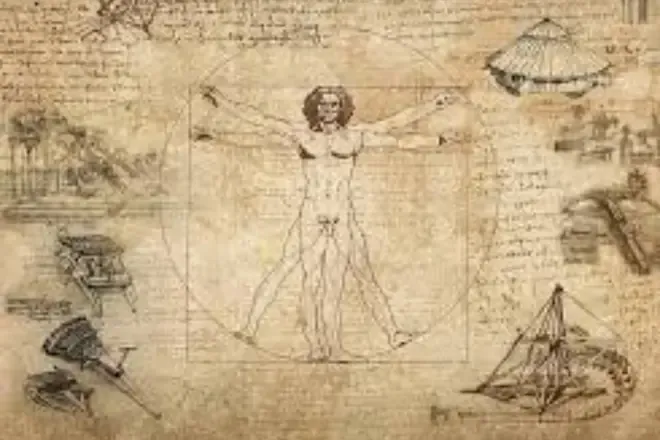

Leonardo da Vinci was a master of art, science, and engineering, and his aerial screw is one of his most fascinating inventions. Sketched around 1480, the aerial screw was a wooden structure with a spiral blade, designed to “screw” into the air and lift off the ground. Think of it as an early helicopter concept. The design featured a large, fabric-covered spiral rotor, about 15 feet wide, powered by human effort—four people would turn a crank to spin the blade.

While the aerial screw couldn’t fly due to the limitations of materials and power in da Vinci’s time, it showed his deep understanding of aerodynamics. He believed that spinning the screw would compress the air beneath it, creating lift. This was centuries before powered flight became a reality, making the aerial screw a testament to his visionary thinking.

Why the Aerial Screw Matters Today

You might wonder how a 500-year-old sketch applies to our high-tech world. The answer lies in drones. Drones are everywhere—delivering packages, filming movies, inspecting infrastructure, and even aiding in disaster relief. But they come with challenges: they’re noisy, energy-hungry, and can disturb people and wildlife. This is where da Vinci’s aerial screw comes in.

Modern engineers have revisited the aerial screw to address these issues. Its unique spiral design creates lift differently than standard drone propellers, offering solutions for quieter and more efficient flight. Let’s dive into how this ancient concept is being adapted for today’s needs.

Reducing Drone Noise Pollution

Drones are loud. Their high-pitched buzzing comes from fast-spinning propellers, which can be a nuisance in cities, near hospitals, or in wildlife areas. Noise pollution isn’t just annoying—it can stress animals, disrupt sleep, and make drones less practical for tasks like nighttime deliveries.

Researchers at the University of Maryland have developed a drone called Crimson Spin, inspired by da Vinci’s aerial screw. Unlike traditional propellers, which spin at high speeds and create a loud whine, the aerial screw’s spiral rotor turns more slowly. This slower rotation cuts broadband noise by about 50%, making drones much quieter. The spiral design also produces a smoother airflow, reducing the turbulent “whooshing” sound that conventional drones make.

For example, imagine a drone delivering medical supplies to a hospital. A quieter drone means less disturbance for patients and staff, making it a game-changer for urban environments or sensitive areas like nature reserves.

Improving Energy Efficiency

Drones don’t just need to be quiet—they need to be efficient. Most drones rely on battery power, and their fast-spinning propellers drain energy quickly. This limits flight time and range, which is a problem for tasks like long-distance deliveries or extended aerial filming.

The aerial screw’s design offers a fix. Its spiral shape creates a unique vortex of air that generates lift more efficiently than standard propellers. Tests by Johns Hopkins University show that aerial screw-inspired rotors use less mechanical power while maintaining comparable lift. This means drones can fly longer on a single charge, saving energy and reducing costs.

For businesses, this could mean cheaper drone operations. For the environment, it means a smaller carbon footprint, as drones require less frequent charging and can carry heavier loads without needing bigger batteries.

Enhancing Safety and Stability

Another advantage of the aerial screw is its aerodynamic stability. Traditional drone propellers create strong downward air currents, called downwash, which can kick up dust, debris, or even cause instability in windy conditions. The aerial screw’s spiral design produces a gentler, spiraling airflow, reducing downwash and making drones safer to operate in tight spaces or near people.

This stability is especially useful for applications like aerial photography, where drones need to hover steadily, or for inspections in confined areas like bridges or wind turbines. Da Vinci’s design, even in its modern form, helps drones operate more safely and reliably.

How Modern Technology Brings the Aerial Screw to Life

In da Vinci’s time, the aerial screw was impractical. It was made of heavy wood and linen, and human power wasn’t enough to get it off the ground. Today, advances in technology have made it possible to turn his vision into reality. Here’s how:

- Lightweight Materials: Modern drones use carbon fiber, aluminum, and advanced plastics, which are strong yet light. These materials make the aerial screw’s large, spiral rotor feasible without adding too much weight.

- Electric Motors: Powerful, compact electric motors can spin the screw at the right speed to generate lift, something da Vinci’s human-powered cranks couldn’t achieve.

- Computer-Aided Design (CAD): Engineers use CAD software to simulate and optimize the aerial screw’s aerodynamics, ensuring it performs well in real-world conditions.

- 3D Printing: Rapid prototyping with 3D printing allows researchers to test and refine spiral rotor designs quickly and affordably.

These advancements have turned da Vinci’s sketch into a practical solution. The Crimson Spin quadcopter, for example, uses four spiral rotors inspired by the aerial screw, proving that his concept works in modern drones.

Real-World Applications of Aerial Screw-Inspired Drones

The potential for aerial screw-inspired drones is huge. Here are some ways they could transform industries and daily life:

- Drone Deliveries: Quieter, more efficient drones could make doorstep deliveries more practical, especially in cities where noise complaints are common.

- Aerial Filming: Filmmakers want drones that are quiet and stable for smooth, high-quality shots. The aerial screw’s design fits the bill.

- Environmental Monitoring: In wildlife preserves, quieter drones can monitor animals without scaring them, helping conservation efforts.

- Disaster Response: Drones with longer flight times and gentler airflow can deliver supplies or survey damage in hard-to-reach areas without stirring up debris.

- Urban Planning: Inspecting buildings or infrastructure with stable, low-noise drones reduces disruption in crowded cities.

These applications show how da Vinci’s idea, once a dream, is now solving practical problems in our world.

What Leonardo da Vinci Teaches Us About Innovation

The aerial screw’s modern revival is more than just a cool engineering story—it’s a lesson in timeless creativity. Leonardo da Vinci wasn’t constrained by the limits of his time. He combined art, science, and imagination to dream up solutions that were centuries ahead. His work inspires us to think boldly and explore new possibilities, even when the tools to make them real don’t yet exist.

For today’s innovators—whether engineers, designers, or entrepreneurs—da Vinci’s example shows the value of:

- Interdisciplinary Thinking: He blended art, anatomy, and physics to create his designs. Today’s problems need similar cross-disciplinary approaches.

- Embracing Failure: The aerial screw didn’t work in the 1480s, but that didn’t stop da Vinci from sketching it. Failure is part of innovation.

- Visionary Curiosity: Da Vinci asked “what if?” and imagined flight long before it was possible. That kind of curiosity drives progress.

Challenges and Future Potential

While the aerial screw is promising, it’s not perfect yet. Spiral rotors are more complex to manufacture than standard propellers, which could increase costs. They also require precise engineering to balance lift, stability, and durability. Researchers are still testing how these rotors perform in different weather conditions or with heavier payloads.

But the future looks bright. As 3D printing and materials science advance, manufacturing costs will likely drop. Ongoing research at universities and companies will refine the design, making it more practical for widespread use. In the coming years, we could see aerial screw-inspired drones buzzing—or rather, quietly humming—above our cities.

A Legacy That Soars

Leonardo da Vinci’s aerial screw is more than a historical curiosity—it’s a reminder that great ideas can stand the test of time. By inspiring quieter, more efficient drones, this 500-year-old design is helping solve modern problems in noise pollution, energy use, and safety. It also teaches us that innovation requires bold thinking, a willingness to experiment, and a touch of imagination.

As we look to the future, da Vinci’s legacy encourages us to keep dreaming big. Who knows what other sketches from the past might inspire the next big breakthrough? For now, the aerial screw reminds us that even in a world of cutting-edge tech, the spark of genius from centuries ago can still light the way.

Want to learn more about drones or da Vinci’s inventions? Check out our other posts on innovation and technology, or share your thoughts in the comments below!